Nanofibers

We study on the preparation and characterization of nanofibers prepared using the microchannel wet-spinning process.

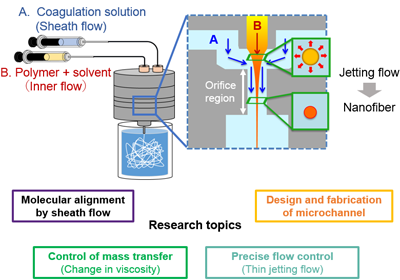

Microchannel Wet-spinning Process

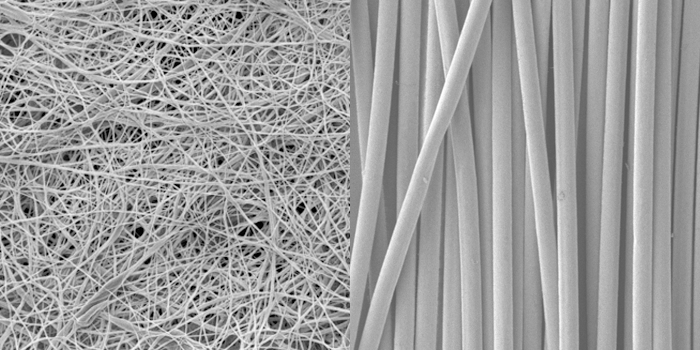

We propose a novel process to produce nanofibers called, “Microchannel Wet-spinning Process”. By applying “flow-focusing” and “solvent diffusion” to the stable jet flow formed in the microchannel, the fluid diameter can be reduced to 1/1000 at room temperature, and polymer nanofibers can be prepared continuously. This technique can be also called “Jet-to-Fiber technology”.

We propose a novel process to produce nanofibers called, “Microchannel Wet-spinning Process”. By applying “flow-focusing” and “solvent diffusion” to the stable jet flow formed in the microchannel, the fluid diameter can be reduced to 1/1000 at room temperature, and polymer nanofibers can be prepared continuously. This technique can be also called “Jet-to-Fiber technology”.

We study on the design of devices for stable production of large quantities of nanofibers, fiber preparation conditions for various raw materials, control of fiber coagulation conditions and molecular orientation to obtain high-strength fibers, and fiber collection technology for the secondary processing.

- Reference

WO2012029710

Example| Biodegradable Polymer Fibers

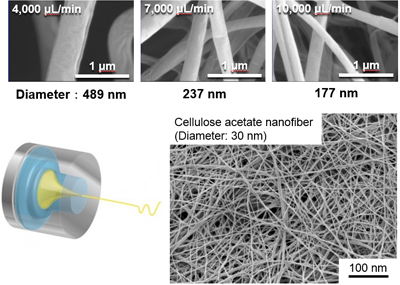

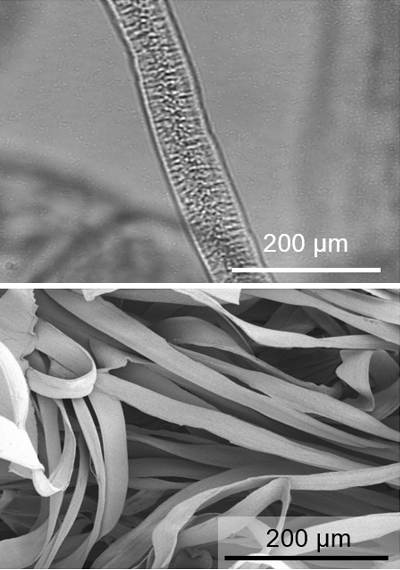

Biodegradable polymer nanofibers are prepared by using bioplastics such as poly(lactic acid) (PLA) and cellulose acetate as raw materials. The fiber diameter can be easily controlled by the feeding rate of the raw material.

Biodegradable polymer nanofibers are prepared by using bioplastics such as poly(lactic acid) (PLA) and cellulose acetate as raw materials. The fiber diameter can be easily controlled by the feeding rate of the raw material.

- Example of the raw materials

Poly(lactic acid)

Poly(ethylene glycol)-block-poly(lactic acid) (PEG-b-PLA)

Cellulose acetate

Example| Ribbon-shaped Fibers

We have succeeded in preparing fibers with various shapes by changing the solvent in the feed solution or altering the solvent diffusion behavior. For example, poly(lactic acid) and polyacrylonitrile fibers with a ribbon-shaped structure can be prepared by the microchannel wet-spinning process. The ribbon-shaped fibers can change the texture and grip of the products.

We have succeeded in preparing fibers with various shapes by changing the solvent in the feed solution or altering the solvent diffusion behavior. For example, poly(lactic acid) and polyacrylonitrile fibers with a ribbon-shaped structure can be prepared by the microchannel wet-spinning process. The ribbon-shaped fibers can change the texture and grip of the products.

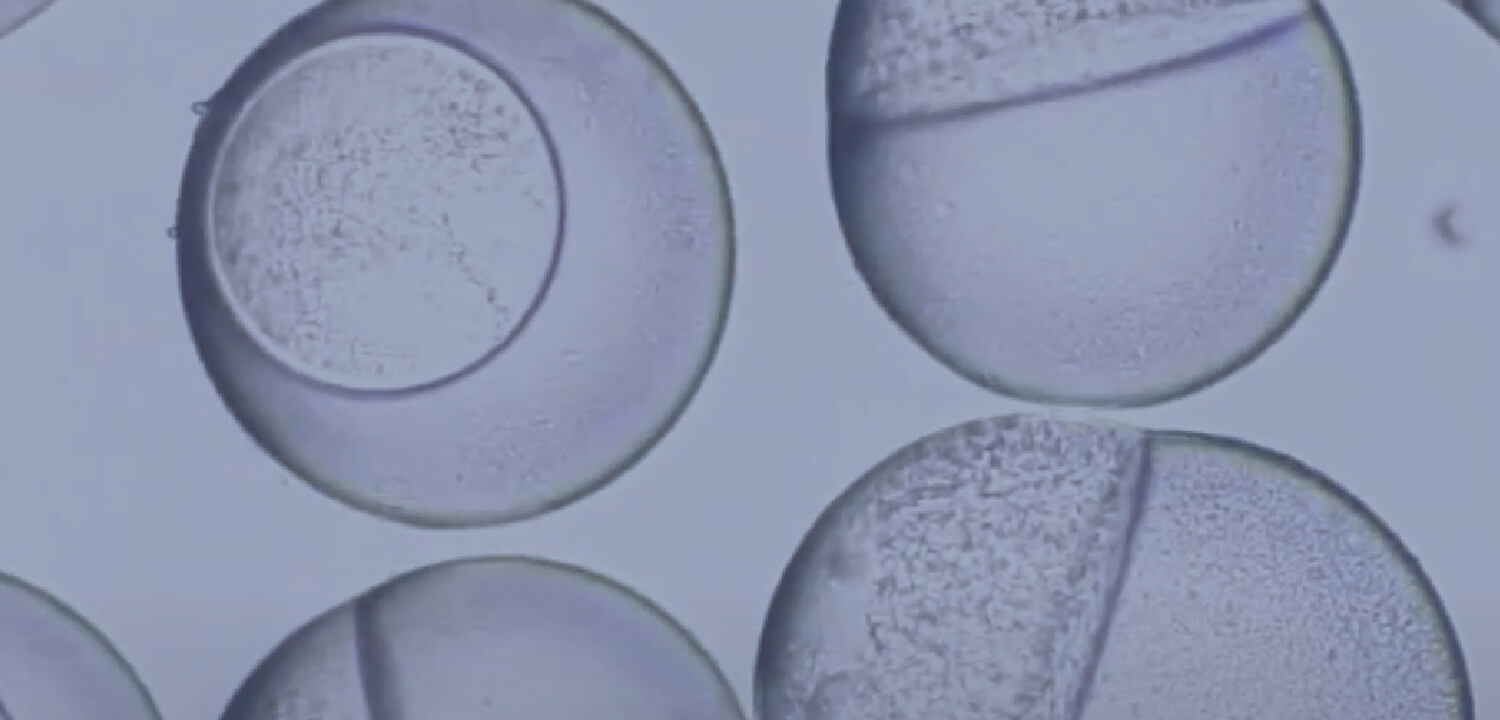

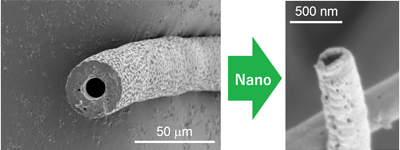

Example| Hollow Nanofibers (Control of Internal Structure)

When a poor solvent of the polymer is added to the feed solution for fiber preparation, phase separation due to solvent diffusion is induced, and porous and hollow fibers can be prepared in the same spinning process. Such hollow fibers are expected to be applied as highly insulating and soundproofing fibers.

When a poor solvent of the polymer is added to the feed solution for fiber preparation, phase separation due to solvent diffusion is induced, and porous and hollow fibers can be prepared in the same spinning process. Such hollow fibers are expected to be applied as highly insulating and soundproofing fibers.

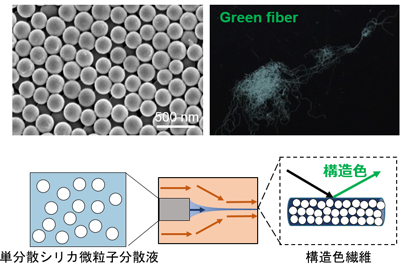

Example| Fibers with a Structural Color

The microchannel wet-spinning process can be used to prepare fibers from solid dispersions as well as polymers. For example, nanoparticles of uniform sizes show structural colors when they are aligned. When water, the dispersant, is removed from a suspension containing silica particles as the feed solution, the silica particles precipitate into fibers. These fibers exhibit the same green structural color as the raw material. Structural color fibers are expected to be applied to apparel materials as they do not need pigments or dyes to keep their color from fading.

The microchannel wet-spinning process can be used to prepare fibers from solid dispersions as well as polymers. For example, nanoparticles of uniform sizes show structural colors when they are aligned. When water, the dispersant, is removed from a suspension containing silica particles as the feed solution, the silica particles precipitate into fibers. These fibers exhibit the same green structural color as the raw material. Structural color fibers are expected to be applied to apparel materials as they do not need pigments or dyes to keep their color from fading.

- Reference

M. Kohri et al., ACS Appl. Mater. Interfaces 10, 7640–7648 (2018)

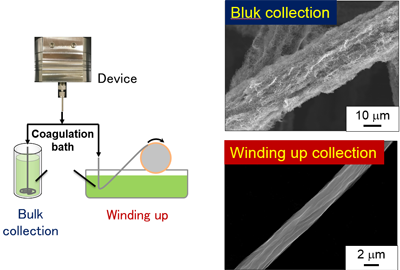

Example| Carbon Nanotube(CNT) Fiber

In the microchannel wet-spinning process, further improvement of the fiber properties can be expected by collecting the fibers via winding up. For example, when preparing fibers from an aqueous solution containing dispersed carbon nanotubes, if the fibers are collected directly in the coagulation bath, a nonwoven fabric with a fluffy surface of CNT fibers is obtained. On the other hand, when the fibers are collected by winding up, the fiber diameter is reduced due to stretching and the breaking strength is improved. We believe that this increase in breaking strength is due to the improved molecular orientation of CNTs. Such CNT fibers are expected to be applied as conductive fibers.

In the microchannel wet-spinning process, further improvement of the fiber properties can be expected by collecting the fibers via winding up. For example, when preparing fibers from an aqueous solution containing dispersed carbon nanotubes, if the fibers are collected directly in the coagulation bath, a nonwoven fabric with a fluffy surface of CNT fibers is obtained. On the other hand, when the fibers are collected by winding up, the fiber diameter is reduced due to stretching and the breaking strength is improved. We believe that this increase in breaking strength is due to the improved molecular orientation of CNTs. Such CNT fibers are expected to be applied as conductive fibers.

Mass Production of Nanofibers

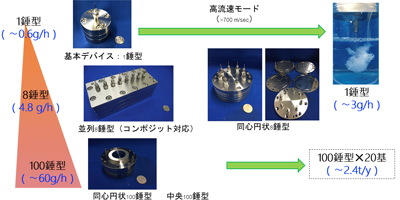

In order to improve the low productivity of nanofibers using a single hole device, which is a drawback of nanofiber production, we study on the development of devices for mass production by combining “internal numbering up” to increase the number of nozzles in one device and “external numbering up” to increase the number of devices.

In order to improve the low productivity of nanofibers using a single hole device, which is a drawback of nanofiber production, we study on the development of devices for mass production by combining “internal numbering up” to increase the number of nozzles in one device and “external numbering up” to increase the number of devices.