Particles and Capsules

We develop material preparation processes for functional particles and capsules using a microchemical process and polymerization process.

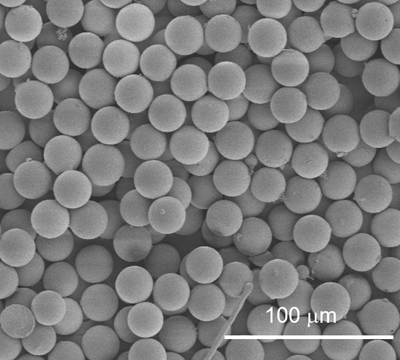

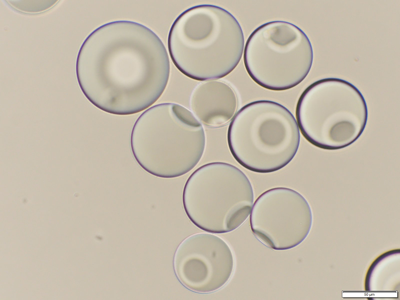

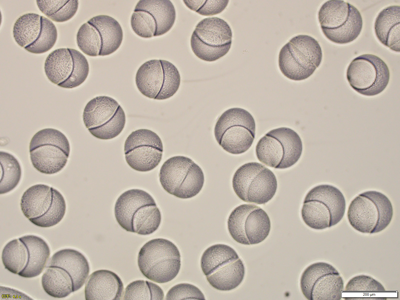

Monodisperse Polymer Particles Prepared Using Solvent Diffusion

Ethyl acetate is an organic solvent with high solubility in water. Therefore, in the preparation of microparticles using ethyl acetate/water emulsion, the polymer is precipitated and microparticles are obtained simply by pouring the prepared emulsion directly into a large amount of water. In our laboratory, we call this simple particle preparation method ”Solvent diffusion method” and apply it to various particle preparations. For example, monodisperse poly(lactic acid) (PLA) particles can be prepared continuously by combining emulsification using a microfluidic device with the solvent diffusion method. This method is applicable not only to PLA but also to any other polymer soluble in solvent.

Ethyl acetate is an organic solvent with high solubility in water. Therefore, in the preparation of microparticles using ethyl acetate/water emulsion, the polymer is precipitated and microparticles are obtained simply by pouring the prepared emulsion directly into a large amount of water. In our laboratory, we call this simple particle preparation method ”Solvent diffusion method” and apply it to various particle preparations. For example, monodisperse poly(lactic acid) (PLA) particles can be prepared continuously by combining emulsification using a microfluidic device with the solvent diffusion method. This method is applicable not only to PLA but also to any other polymer soluble in solvent.

- Reference

T. Watanabe et al., Soft Matter 7, 9894–9897 (2011)

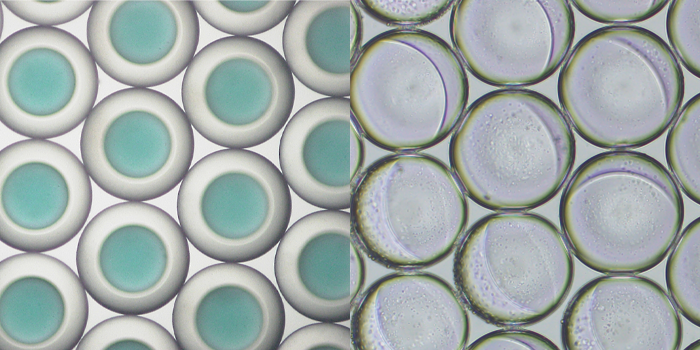

Oil-filled Microcapsules by Internal Phase Separation within Droplets

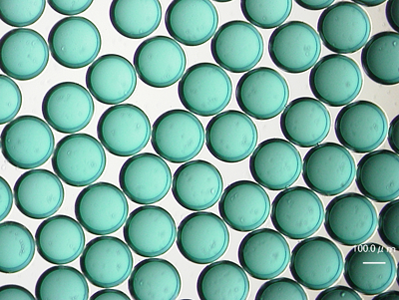

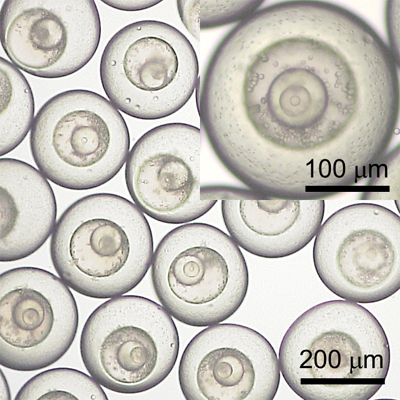

Monodisperse microcapsules encapsulating oil (poor solvent) can be prepared by phase separation of the polymer-rich phase and the poor solvent in monodisperse droplets prepared using a microfluidic channel. This technique can be applied to various combinations of polymer and oil. In our laboratory, we develop microcapsules applicable for heat storage and contrast agent using this technique.

Monodisperse microcapsules encapsulating oil (poor solvent) can be prepared by phase separation of the polymer-rich phase and the poor solvent in monodisperse droplets prepared using a microfluidic channel. This technique can be applied to various combinations of polymer and oil. In our laboratory, we develop microcapsules applicable for heat storage and contrast agent using this technique.

- Reference

T. Watanabe et al., Langmuir 29, 14082–14088 (2013)

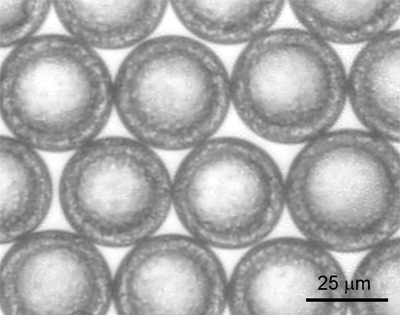

Melamine Microcapsules

Melamine-formaldehyde microcapsules can be prepared by in situ polymerization using oil-in-water (O/W) emulsion as a template. This process has been known for a long time, but due to the complexity of the polymerization mechanism, the detail of the mechanism is still unclear.

Melamine-formaldehyde microcapsules can be prepared by in situ polymerization using oil-in-water (O/W) emulsion as a template. This process has been known for a long time, but due to the complexity of the polymerization mechanism, the detail of the mechanism is still unclear.

We investigate new shell materials that can be applied to this method and study the mechanism of shell formation. We also study the application of microcapsules as heat storage materials.

- References

T. Tsuneyoshi et al., Mater. Sci. Eng. B 222, 49–54 (2017)

E. Kamio et al., Colloid Polym. Sci., 287, 787–793 (2008)

E. Kamio et al., Langmuir 24, 13287–13298 (2008)

Hydrogel Microcapsules Prepared Using ATPS Droplets

Phase separation generally occurs between substances with completely different properties, such as water and oil. When “polymers and salts” or ”two kinds of polymers” are dissolved in water at high concentrations, phase separation even occurs in the aqueous solution and each substance is separated into a concentrated phase. Such a phase separation state of an aqueous solution is called an “Aqueous Two-Phase System (ATPS)”.

Phase separation generally occurs between substances with completely different properties, such as water and oil. When “polymers and salts” or ”two kinds of polymers” are dissolved in water at high concentrations, phase separation even occurs in the aqueous solution and each substance is separated into a concentrated phase. Such a phase separation state of an aqueous solution is called an “Aqueous Two-Phase System (ATPS)”.

We have succeeded in preparing Water-in-Water-in-Oil (W/W/O) emulsions by inducing ATPS in monodisperse water droplets. Furthermore, by crosslinking reaction only in the intermediate phase, we have succeeded in preparing hydrogel capsules in which the water droplets are covered with a hydrogel shell. Such soft materials are expected to be applied as bioreactors and transplantation medicine.

- References

M. Yasukawa et al., ChemPhysChem 12, 263–266 (2011)

T. Watanabe et al., Langmuir 35, 2358–2367 (2019)

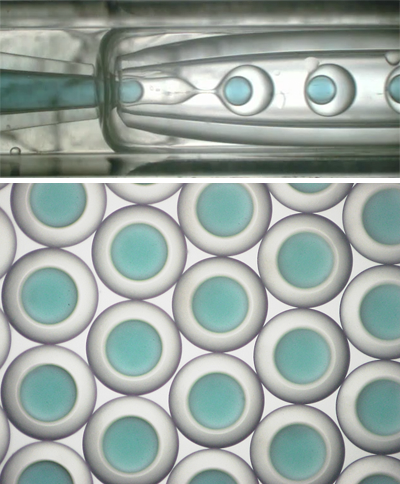

Double Emulsion

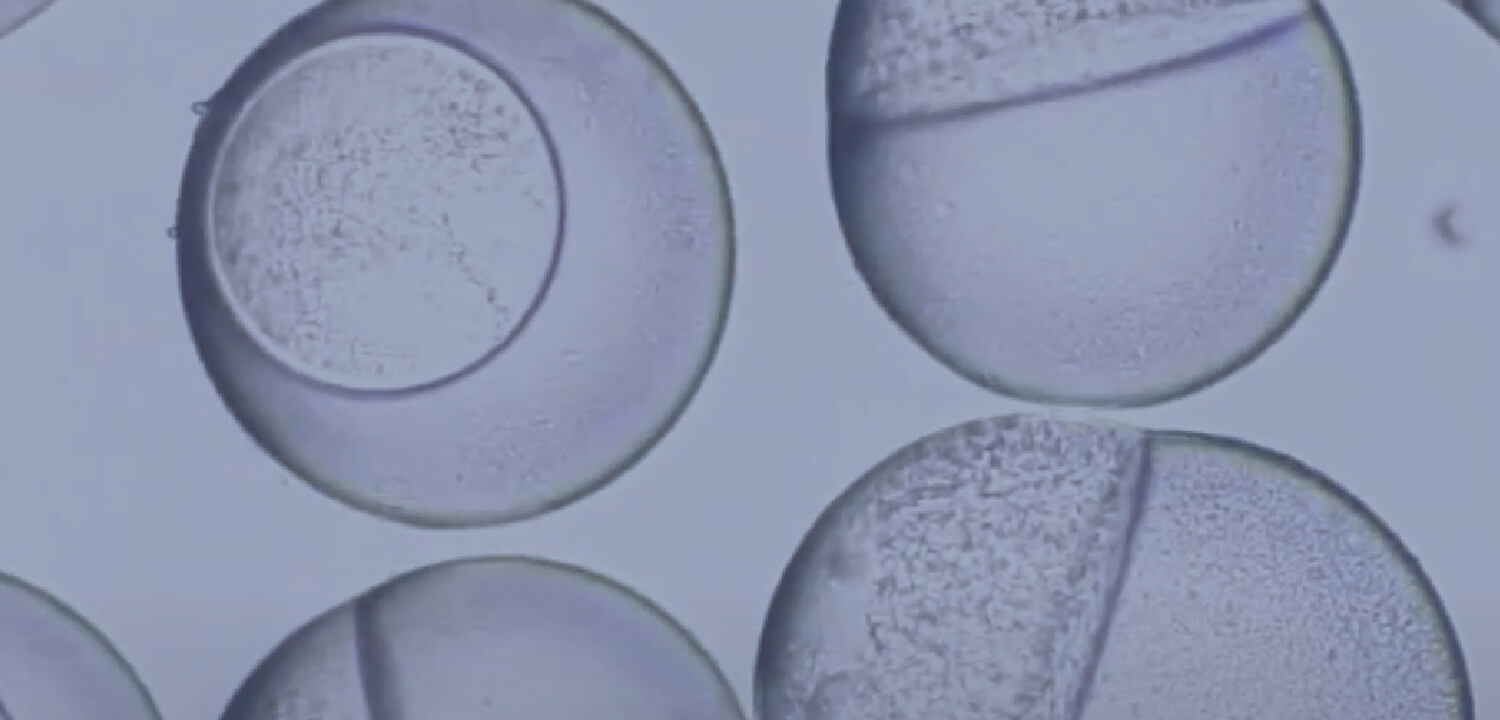

Microfluidic technology allows us to prepare monodisperse and mononuclear water-in-oil-in-water (W/O/W) emulsions (Double emulsion), which are difficult to prepare by conventional mechanical emulsification methods.

Microfluidic technology allows us to prepare monodisperse and mononuclear water-in-oil-in-water (W/O/W) emulsions (Double emulsion), which are difficult to prepare by conventional mechanical emulsification methods.

We study on the preparation of giant liposomes and water-encapsulated microcapsules using double emulsions as templates.

Water-filled Microcapsules

When the middle phase of double emulsions is solidified by solvent evaporation, solvent diffusion, or photo-polymerization methods, polymeric microcapsules with a single aqueous core can be prepared. Such water-encapsulated microcapsules are useful colloidal materials for drug delivery carriers, cosmetics, and foods.

When the middle phase of double emulsions is solidified by solvent evaporation, solvent diffusion, or photo-polymerization methods, polymeric microcapsules with a single aqueous core can be prepared. Such water-encapsulated microcapsules are useful colloidal materials for drug delivery carriers, cosmetics, and foods.

We study on the preparation of water-encapsulated microcapsules using a variety of materials and evaluate how the membrane structure affects the sustained release of the inclusions.

Janus Hydrogel Particles

In the world of fine particles, particles with different properties in each hemisphere are called Janus particles. For example, if one hemisphere has a high affinity for oil and the other for water, the Janus particles will act as stabilizers to stabilize the interface between water and oil.

In the world of fine particles, particles with different properties in each hemisphere are called Janus particles. For example, if one hemisphere has a high affinity for oil and the other for water, the Janus particles will act as stabilizers to stabilize the interface between water and oil.

Our laboratory has successfully prepared Janus-type hydrogel microparticles by adjusting the interfacial tension and phase separation rate in the preparation of microparticles and microcapsules by internal phase separation. These microparticles are expected to be used as stabilizers for Water-in-Water (W/W) emulsions.

- Reference

T. Watanabe et al., Langmuir 35, 2358–2367 (2019)

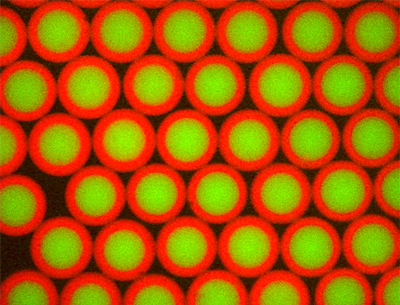

Multilayer Microcapsules Prepared by Sequential Phase Separation

Multilayer emulsions and microcapsules are prepared via a multi-step emulsification process. However, this method is rarely realized due to its complexity.

Multilayer emulsions and microcapsules are prepared via a multi-step emulsification process. However, this method is rarely realized due to its complexity.

We have found that the removal of co-solvent from a uniform droplet flowing in a microfluidic channel leads to sequential phase separation in the droplet and reproducible formation of triple- to quintuple-structured droplets. Furthermore, by polymerizing these monomer phases in the microchannel, microcapsules with a multilayered structure can be prepared continuously. We study the formation mechanism of microcapsules with such non-equilibrium structures and their functional properties.

- Reference

T. Watanabe et al., ACS Appl. Polymer Mater., 4(1), 348–356 (2022), Selected as ACS Editor’s Choice

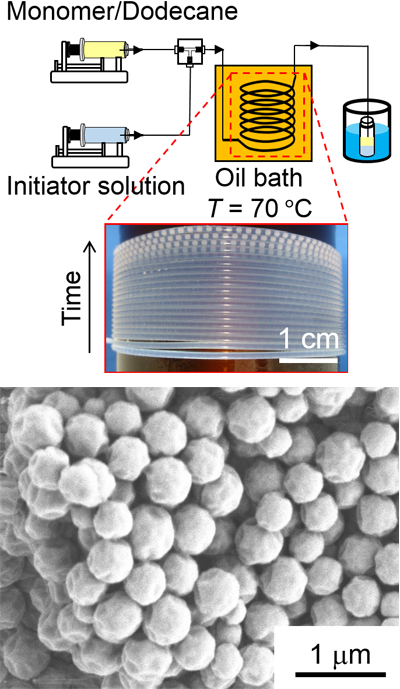

Flow Synthesis of Polymer Particles by Polymerization in Slug

When water and oil are pumped into a microchannel at constant velocity, an alternating flow called a “Slug flow” is formed. The slug flow in the microchannel has the following features: (1) fast heat transfer due to the narrow channel width, and (2) excellent mass transfer due to the internal circulation flow of the slug.

When water and oil are pumped into a microchannel at constant velocity, an alternating flow called a “Slug flow” is formed. The slug flow in the microchannel has the following features: (1) fast heat transfer due to the narrow channel width, and (2) excellent mass transfer due to the internal circulation flow of the slug.

By using the slug flow as a reaction loci for soap-free emulsion polymerization or seeded soap-free emulsion polymerization instead of a batch reactor, we have succeeded in the rapid continuous preparation of submicron to single micron-sized polymer particles.

- References

E. Kamio et al., Ind. Eng. Chem. Res., 50, 6915–6924 (2011)

T. Watanabe et al., Macromol. Phys. Chem., 220, 1900021 (2019)

T. Watanabe et al., Colloid Polym. Sci., 298, 1273–1281 (2020)

T. Watanabe et al., Front. Chem. Eng., 3, 63 (2021)